Pushout Casement Hardware

Pushout Casement Hardware

Parrett awnings are available with a variety of pushout hardware configurations, as opposed to more common crankout hardware applications. Typical pushbars and handles/latches are shown below. Based on the size and weight of the awning sash, Parrett can recommend an optimal hardware solution.

Parrett works with a large variety of hardware vendors and can also source custom hardware. The selections below have been time-tested by Parrett to provide optimal performance. For additional pushout awning hardware configurations please view our Rotating Awning page for more information.

Pushout Handle Options

Fig. 20 - A traditional design handle for push out casement windows that uses European multipoint latching mechanisms.

Handle: 3-1/2"

Overall Depth: 1-7/8"

Base Dim.: 3/4" x 2-3/8"

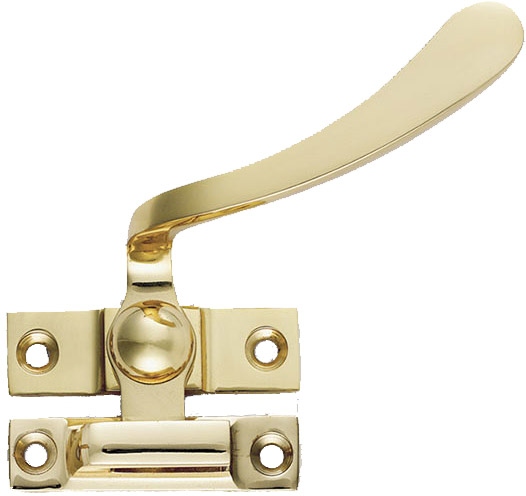

Fig. 21 - Another elegant, traditional design fastener for units not utilizing a multipoint locking gear.

Handle: 3-1/2"

Overall Depth: 1-7/8"

Base Dim.: 11/16" x 2-3/8"

Fig. 22 - Similar function to Fig. 21, with a smaller handle and a unique, aesthetic design.

Handle: 2"

Overall Depth: 1-1/4"

Base Dim.: 11/16" x 2-3/8"

Pushbar Options

Typically a pushout awning with historic pushbars will have a pushbar on each vertical side of the frame that attaches to the vertical sides of the sash.

Length: 12-1/2"

Overall Height: 2-3/8"

Overall Depth: 1-3/8"

Length: 10-1/2" or 16"

Overall Height: 1-1/4"

Overall Depth: 1-1/8"

Length: 13-1/2"

Overall Height: 2"

Base dim: 15/16" x 2-3/8"

Pushout Hardware Finishes

The finishes below area available for the hardware shown on this page. Parrett also offers custom plating solutions and other hardware finishes, contact us at info@parrettwindows.com for more information.

Polished Lacquered Brass (PB) - The standard finish for most items.

Polished Unlacquered Brass (PBNL) - This finish, though bright when new, will tarnish quickly through use and exposure, to a natural antique finish.

Oil Rubbed Bronze (OB) - A rich, deep, brown finish, produced by oxidation of the brass metal, and protected by a matte lacquer. Over time the areas of the hardware exposed to wear will become lighter and more polished by use, resulting in the appearance of antique bronze.

Satin Nickel (SN) - This finish is produced by lightly polishing a dull nickel plating with a fine abrasive brush. The result is a clean, functional look, not unlike pewter or brushed stainless steel.

Polished Nickel (PN) - This is a smooth, rich, and highly polished finish, often found on high quality bathroom fixtures. Polished nickel has a warmer appearance when compared to chrome plating.